Laser-Induced Breakdown Spectroscopy (LIBS) uses a focused laser pulse to quickly analyze the elemental makeup of a material. When you target a sample, the laser creates a plasma by instantly ionizing its surface, which then emits light with specific wavelengths. These spectral lines act as unique signatures for each element, allowing for rapid, non-destructive detection of even trace substances. If you keep exploring, you’ll discover how this technology is transforming material analysis across many fields.

Key Takeaways

- LIBS uses focused laser pulses to create plasma from the sample surface for elemental analysis.

- The plasma emits light with specific spectral lines unique to each element.

- Spectral analysis of emitted light allows rapid, non-destructive identification of material composition.

- The technique enables real-time, in situ analysis of solids, liquids, and gases.

- Advancements in spectral resolution improve LIBS accuracy and broaden its scientific and industrial applications.

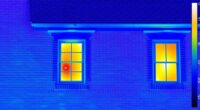

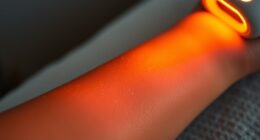

Have you ever wondered how scientists determine the composition of a material so quickly and accurately? Laser-induced breakdown spectroscopy, or LIBS, makes this possible by using a focused laser pulse to analyze materials in real time. When you direct a high-energy laser beam onto a sample’s surface, it instantly creates a plasma—a hot, ionized cloud of atoms and electrons. This plasma formation is the key to LIBS because it temporarily breaks down the material into its fundamental components, allowing you to examine its elemental makeup.

Once the plasma forms, it begins to cool rapidly, and as it does, the excited atoms and ions emit light at specific wavelengths. This is where spectral analysis comes into play. By capturing and analyzing the emitted light, you can identify the elements present in the sample with remarkable speed. Each element has a unique spectral signature, a set of characteristic wavelengths, which makes it straightforward to distinguish between different elements. The process is highly sensitive, often capable of detecting trace amounts of substances, and can be performed in situ without extensive sample preparation.

Spectral analysis quickly identifies elements by their unique light signatures, detecting traces without extensive prep.

The entire process hinges on the interplay between plasma formation and spectral analysis. When the laser pulse hits the material, energy is transferred almost instantaneously, causing a rapid rise in temperature and ionization, resulting in plasma creation. The properties of this plasma—its temperature, electron density, and emission spectrum—are directly related to the sample’s composition. By analyzing the emitted spectral lines, you effectively get a fingerprint of the material’s elemental makeup. This method allows for quick, non-destructive testing, which is invaluable across industries such as environmental monitoring, metallurgy, and even space exploration.

Moreover, spectral analysis provides real-time feedback, enabling you to make immediate decisions based on the data. For example, in quality control processes, LIBS can quickly verify the presence of specific elements in a product or raw material. Because it’s based on optical emission, the technique requires minimal sample preparation and can be performed on solids, liquids, or gases. The ability to perform rapid, precise, and in-situ elemental analysis makes LIBS a powerful tool that’s transforming how you can inspect, monitor, and understand materials.

In addition, advancements in spectral resolution and instrumentation are continually expanding LIBS capabilities, allowing for even more precise and comprehensive elemental analysis.

In essence, LIBS combines the physics of plasma formation with the precision of spectral analysis to deliver instant insights into a material’s composition. It’s a cutting-edge technology that bridges complex atomic interactions with practical applications, all in a matter of seconds, making it an essential tool in modern analytical science.

Frequently Asked Questions

How Does LIBS Compare to Other Spectroscopic Techniques in Accuracy?

You’ll find LIBS offers competitive accuracy compared to other spectroscopic methods, thanks to its high spectral resolution and detection sensitivity. It can quickly identify elements even at low concentrations, making it useful for real-time analysis. While techniques like ICP-MS may provide higher precision, LIBS’s portability and speed make it a strong choice for many applications. Overall, its balance of accuracy, speed, and versatility makes it stand out among other spectroscopy methods.

What Are the Limitations of Laser Energy in LIBS Applications?

Like a fragile flame, your laser energy faces limitations in LIBS applications. You’re constrained by laser power, which caps the intensity of the plasma and affects detection sensitivity. Energy source constraints mean you can’t always achieve ideal ablation or spectral resolution. These restrictions restrict your ability to analyze samples thoroughly, especially in challenging environments or with delicate materials. Managing and optimizing laser energy is vital to overcoming these inherent limitations.

Can LIBS Be Used for Real-Time In-Field Analysis?

Yes, LIBS can be used for real-time in-field analysis. You can benefit from portable analysis and handheld devices, which allow you to quickly identify materials on-site. These devices provide rapid results, making them ideal for field applications like environmental monitoring, mining, or law enforcement. Their portability and speed help you make immediate decisions without waiting for lab results, improving efficiency and responsiveness in various industries.

How Does Sample Surface Roughness Affect LIBS Results?

Surface roughness impacts LIBS results by affecting measurement precision and surface texture. When the surface is uneven, it causes inconsistent laser ablation, leading to variable plasma formation and spectral signals. This variability makes it harder to obtain accurate, repeatable measurements. To improve LIBS accuracy, you should smooth the sample surface or use multiple measurements. Consistent surface texture helps guarantee reliable results and enhances overall measurement precision.

What Safety Precautions Are Necessary When Operating LIBS Equipment?

When operating LIBS equipment, you need to prioritize laser safety by wearing appropriate personal protective equipment like safety goggles, gloves, and lab coats. Always follow the manufacturer’s safety guidelines and make certain the area has proper signage and barriers. Never look directly into the laser or point it at others. Regularly check equipment for damage, and receive proper training to handle emergencies, guaranteeing both your safety and accurate results.

Conclusion

You now understand how Laser-Induced Breakdown Spectroscopy (LIBS) works, using a laser pulse to analyze material composition instantly. Did you know LIBS can detect elements at parts-per-million levels? This technique’s speed and sensitivity make it invaluable across industries, from environmental monitoring to space exploration. By mastering LIBS, you’re tapping into a powerful tool that offers rapid, precise analysis—revolutionizing how we identify and understand materials in seconds.