For precision measurements from 200nm to 2500nm, I recommend the Laser Testing Integrating Sphere. It offers high reflectivity above 98%, making it ideal for accurate data. Its compact size and versatile connectors like SMA905 and FC ensure easy integration into various laser systems. The durable PTFE material guarantees long-term stability. If you want to discover the top options that combine these features, keep exploring—there’s more that could meet your needs perfectly.

Key Takeaways

- Ensure the sphere covers the full wavelength range from 200nm to 2500nm for comprehensive laser testing.

- Prioritize high reflectivity (above 98%) and smooth interior surfaces for accurate, consistent measurements.

- Choose a compact, durable design with standard SMA905 and FC connectors for seamless integration.

- Verify that the sphere’s material (e.g., PTFE) offers high reflectivity and long-term stability across spectral ranges.

- Select a model with versatile interface options and proven performance for precise laser measurement applications in 2025.

Laser Testing Integrating Sphere for Wavelengths 200nm-2500nm

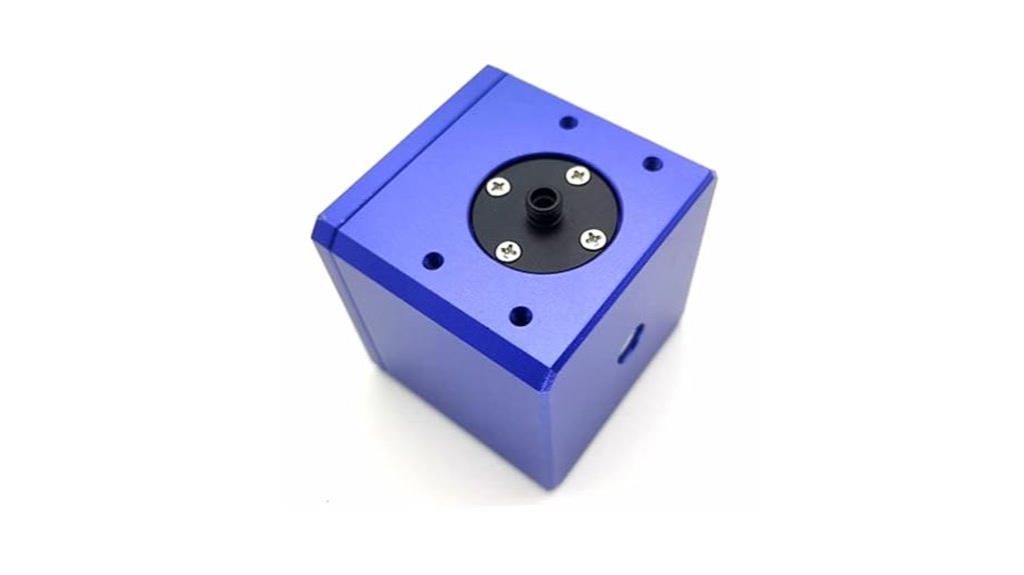

If you’re measuring lasers across a broad spectrum, our Laser Testing Integrating Sphere is the perfect choice. It covers wavelengths from 200nm to 2500nm, ensuring versatility for various laser types. Its compact size, 53mm x 53mm x 51mm, makes it easy to integrate into your setup. The 9mm inlet and 4mm output apertures facilitate efficient light collection and distribution. Made from PTFE with 98.5% reflectivity, it guarantees high accuracy and minimal signal loss. Equipped with SMA905 and FC connectors, it offers compatibility with most laser systems, making it an essential tool for precise laser measurement and testing.

Best For: researchers and engineers requiring precise measurement and testing of lasers across a broad spectrum from 200nm to 2500nm.

Pros:

- High reflectivity of 98.5% ensures accurate light measurement with minimal signal loss.

- Versatile compatibility with SMA905 and FC connectors for easy integration with various laser systems.

- Compact size (53mm x 53mm x 51mm) allows for seamless incorporation into existing setups.

Cons:

- Limited to specific wavelength range (200nm-2500nm), not suitable for wavelengths outside this spectrum.

- PTFE material, while durable, may require careful handling to avoid damage.

- The fixed aperture sizes (9mm inlet and 4mm output) may limit adaptation for certain specialized laser measurements.

Factors to Consider When Choosing Lab‑Grade Integrating Spheres

When selecting a lab-grade integrating sphere, I focus on factors like wavelength compatibility, surface reflectivity, and material durability to guarantee accurate, long-lasting performance. I also consider the size, interface options, and portability to match my testing setup. These choices directly impact measurement quality and ease of use, so I weigh each carefully.

Wavelength Compatibility Range

Choosing a lab-grade integrating sphere requires guaranteeing its effective wavelength range covers all your measurement needs. I look for a sphere that spans the full spectrum relevant to my work, such as 200nm to 2500nm for broad laser testing. It’s vital to verify that the sphere’s reflectivity remains high across this range, ensuring accurate and consistent measurements. The internal coating and materials must be compatible with the tested wavelengths to prevent degradation or errors. I also consider whether the design supports uniform light diffusion at each wavelength, which is essential for reliability. Additionally, I check for suitable optical interfaces, like SMA905 or FC connectors, that facilitate seamless integration at the required wavelengths. Covering these factors ensures my measurements are precise and dependable across all tested spectra.

Reflectivity and Surface Quality

The reflectivity and surface quality of an integrating sphere directly influence measurement accuracy and consistency. High surface reflectivity, typically above 98%, minimizes signal loss and ensures precise light readings. A smooth, uniform surface finish is essential for consistent diffuse reflection across the interior, preventing measurement errors. Materials like PTFE are preferred because they offer high reflectivity and durability, maintaining surface quality over time. Regular inspection and cleaning are vital to preserve reflectivity and prevent degradation that could compromise data accuracy. The surface’s quality impacts how evenly light is distributed inside the sphere, which is critical for reliable measurements. When selecting an integrating sphere, prioritize models with high, stable reflectivity and a well-maintained, smooth interior surface to achieve ideal precision in your experiments.

Connector and Interface Options

Selecting the right connector and interface options is essential for guaranteeing seamless integration and ideal performance of lab-grade integrating spheres. I focus on connectors like SMA905 and FC, as they are common in fiber optic applications and support various laser systems. The choice influences signal stability, ease of connection, and compatibility with different wavelengths and power levels. High-quality spheres often feature standardized interfaces, making it straightforward to connect with measurement equipment and reducing signal loss. Using appropriate connectors guarantees precise, reliable measurements across a broad spectral range. Compatibility with multiple interface options also adds versatility, allowing the sphere to adapt to different testing environments and research setups. Ultimately, choosing the right interface ensures top-notch performance and simplifies integration into your lab workflow.

Size and Portability

Size and portability are key considerations when I evaluate lab-grade integrating spheres, as they directly impact how and where I can use them. Smaller spheres, typically under 100mm in diameter, are easy to carry and ideal for field measurements or quick tests. However, they may have limited light collection capacity, which can affect measurement accuracy. Larger spheres, over 200mm, offer better homogeneity and more precise results, but are bulkier and harder to transport, making them better suited for controlled laboratory settings. The size influences the uniformity of light distribution, with bigger spheres providing more consistent measurements. When choosing, I balance the need for portability against the required measurement precision to optimize workflow and ensure reliable results in different environments.

Material Durability and Stability

Durable materials like PTFE and Spectralon are crucial for guaranteeing that lab-grade integrating spheres maintain their performance over time. These materials resist degradation, preserving reflectivity and measurement accuracy during repeated use. The stability of the sphere’s reflective coating is critical; any deterioration can lead to inconsistent results. Additionally, properties like chemical resistance and temperature tolerance extend the sphere’s lifespan in various lab environments. Proper calibration and regular maintenance are essential to prevent material degradation that could compromise reflectivity. Choosing materials with high environmental stability helps minimize the effects of humidity, UV exposure, and other factors that threaten performance. Ultimately, selecting robust, stable materials ensures your integrating sphere remains reliable, accurate, and durable for precision measurements over the long term.

Frequently Asked Questions

What Are the Maintenance Requirements for High-Precision Integrating Spheres?

Maintaining high-precision integrating spheres involves regular cleaning to prevent dust buildup and guarantee accurate readings. I routinely inspect the interior and wipe it with a soft, lint-free cloth, avoiding harsh chemicals. Calibration checks are essential, so I verify the sphere’s performance periodically with standard light sources. Additionally, I handle the sphere carefully to prevent any physical damage, which could affect measurement accuracy over time.

How Do Integrating Spheres Impact Measurement Accuracy Over Time?

I’ve found that integrating spheres considerably sharpen measurement accuracy over time. Their stability stems from consistent calibration and careful cleaning, which prevent drift and distortion. Regular maintenance minimizes misreads, ensuring measurements remain precise and dependable. Over time, neglecting these steps can cause inaccuracies to creep in, so I always stay vigilant, calibrate routinely, and clean thoroughly. This proactive approach keeps my measurements accurate and my results reliable.

Can Integrating Spheres Be Customized for Specific Laboratory Applications?

Absolutely, integrating spheres can be customized for specific lab applications. I work closely with manufacturers to tailor sphere size, port configuration, and coating materials to suit unique measurement needs. This customization guarantees more accurate, reliable data, especially when dealing with specialized light sources or measurement parameters. If you’re considering a sphere for a particular task, I recommend discussing your requirements with a provider to optimize the design for your specific application.

What Are the Safety Considerations When Using Lab-Grade Integrating Spheres?

Imagine a delicate glass sphere shimmering under lab lights—that’s how I see safety with integrating spheres. I always wear proper eye protection, avoid direct exposure to intense light sources, and verify proper grounding to prevent electrical hazards. Keeping the workspace clean and following manufacturer guidelines helps prevent accidents. Staying alert and cautious ensures I protect my vision, skin, and equipment while capturing precise measurements safely.

How Do Different Coatings Affect the Sphere’s Reflective Properties?

Different coatings considerably influence a sphere’s reflectivity. For instance, a white diffuse coating offers high reflectance across a broad spectrum, ideal for general measurements. Silver coatings provide excellent reflectivity in the visible range but can tarnish over time, reducing performance. Gold coatings excel in infrared applications due to their high reflectance there. I always consider my specific wavelength needs when choosing a coating to guarantee accurate, reliable results.

Conclusion

Choosing the right lab-grade integrating sphere might seem intimidating, but it’s about balancing precision with practicality. While I value the high-end reflectivity and durability, I also appreciate a compact design that fits my workspace. It’s like finding the perfect instrument—powerful yet manageable. Ultimately, selecting the best sphere blends technical specs with real-world needs, ensuring your measurements are both accurate and convenient. After all, precision doesn’t have to come at the expense of ease.