Laser sintering fuses metal powder layer by layer using a high-powered laser that precisely melts the powder in targeted areas. You start with a bed of fine metal particles, which the laser scans to create complex shapes and internal features. Proper control of laser power, speed, powder quality, and environment is vital for strong, accurate parts. If you keep exploring, you’ll discover how process parameters impact final quality and applications.

Key Takeaways

- Uses a high-powered laser to selectively melt metal powder layers, building complex parts layer by layer.

- Powder quality and particle size are critical for uniform melting and strong layer adhesion.

- Laser parameters like power and scan speed must be precisely controlled to ensure complete melting without warping.

- Environmental conditions such as temperature and humidity influence melt quality and final part integrity.

- Post-processing steps like heat treatment enhance mechanical properties and surface finish of the sintered metal parts.

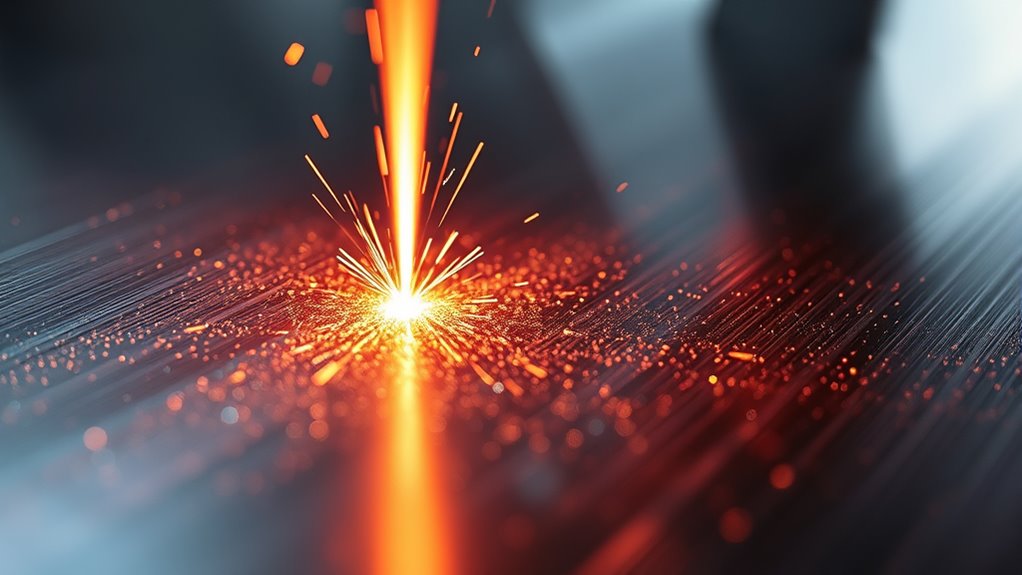

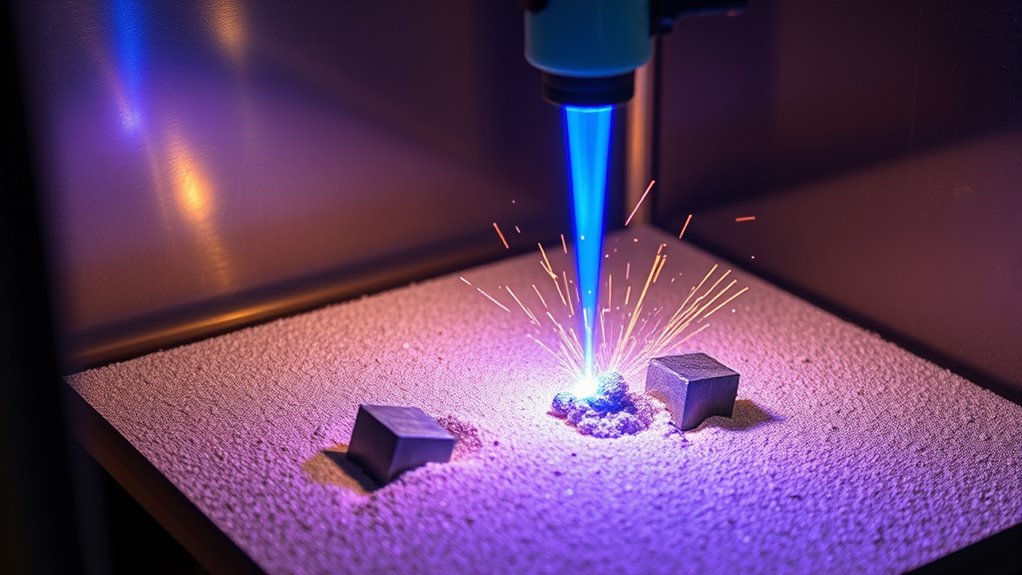

Laser sintering is an innovative additive manufacturing process that uses a high-powered laser to fuse powdered materials into solid objects. When you work with this process, you start with a bed of finely ground metal powder, carefully spread across the build platform. The laser then targets specific areas of this layer, heating the metal powder just enough to melt and bind the particles together. This precise energy application creates a seamless layer fusion, which forms the foundation for the next layer of powder. As each layer is fused, you build the object layer by layer, gradually creating complex shapes that would be difficult or impossible with traditional manufacturing methods.

The success of laser sintering relies heavily on the quality of the metal powder you use. High-quality metal powders are designed to flow smoothly and evenly, ensuring consistent layer thickness. When the laser hits the powder, it must generate enough heat to achieve complete melting without causing warping or distortion. The powder’s particle size and distribution play critical roles here—you want a uniform size to promote even melting and strong layer fusion. When the laser scans across the powder bed, it selectively melts the particles, creating a solid, cohesive structure at each point. This layer fusion is essential for achieving the mechanical properties and dimensional accuracy required for your final product. Additionally, controlling environmental factors such as temperature and humidity during the process can significantly impact the quality of the final parts.

One key advantage of laser sintering is its ability to produce complex geometries directly from digital models. Since the process builds objects layer by layer, you can incorporate intricate internal channels or undercuts that traditional manufacturing would struggle to produce. Additionally, the process is highly repeatable, allowing you to create multiple identical parts with minimal variability. The layer fusion process is rapid and precise, enabling you to reduce lead times and material waste compared to subtractive methods. You can even customize parts on the fly, making it ideal for prototypes, small-batch production, or highly specialized components.

However, mastering laser sintering requires attention to detail, especially in controlling parameters like laser power, scan speed, and layer thickness. These settings influence the quality of layer fusion and the integrity of the final part. Proper post-processing, such as heat treatment or surface finishing, might be necessary to enhance mechanical properties or improve surface quality. Overall, understanding how metal powder properties and laser parameters work together will help you optimize your process, ensuring strong layer fusion and high-quality, durable parts. Being aware of potential security vulnerabilities in the process is also crucial for safeguarding sensitive design data and preventing malicious interference.

Frequently Asked Questions

What Are the Environmental Impacts of Laser Sintering Processes?

You might be concerned about the environmental impacts of laser sintering. It does consume significant energy, which can contribute to carbon emissions if sourced from non-renewable resources. Additionally, powder waste can occur during the process, leading to material wastage. However, optimizing energy use and recycling unused powder can reduce these impacts, making laser sintering more sustainable and environmentally friendly.

How Does Laser Sintering Compare to Other Metal 3D Printing Methods?

You’ll find laser sintering more energy-efficient than methods like direct energy deposition, using about 50% less power. Compared to other metal 3D printing techniques, it offers high precision and better surface finish, reducing waste. Plus, it works well with a variety of metal powders, making it versatile. So, if you want a cleaner, more efficient process, laser sintering is a smart choice for producing complex metal parts.

What Are the Common Post-Processing Steps for Sintered Metal Parts?

You typically perform surface finishing and heat treatment as common post-processing steps for sintered metal parts. Surface finishing improves the part’s appearance and smoothness, while heat treatment enhances mechanical properties like strength and durability. You might also remove any residual powder, perform machining for precision, or apply coatings. These steps guarantee your metal parts meet quality standards and are ready for their intended application.

How Is Layer Adhesion Quality Monitored During the Process?

Think of layer adhesion quality like watching a chef perfect a delicate soufflé; it’s all about timing and temperature. During the process, you can use thermal imaging for real-time monitoring to detect inconsistencies or weak spots in the fusion. This live feedback helps you catch issues early, ensuring each layer bonds properly. By actively tracking these parameters, you maintain high-quality adhesion and prevent costly defects.

What Are the Limitations of Laser Sintering in Large-Scale Manufacturing?

You’ll face scaling challenges with laser sintering in large-scale manufacturing because the process becomes less efficient and more costly as you try to produce bigger quantities. The cost implications include expensive equipment, high energy consumption, and longer build times. These limitations can hinder your ability to meet large orders quickly and affordably, making it less suitable for mass production compared to traditional manufacturing methods.

Conclusion

As you explore laser sintering, imagine building a delicate sculpture layer by layer, each pass like a gentle brushstroke. Just as a master artist transforms raw clay into art, you can turn fine metal powders into intricate creations with precision. This process isn’t just about technology; it’s about crafting your ideas into reality, one layer at a time. Embrace it, and watch your innovations come alive, just like a masterpiece emerging from careful, deliberate strokes.