Hyperspectral imaging revolutionizes food safety checks by offering rapid, non-destructive analysis of food products through detailed spectral data. This technology captures hundreds of spectral bands per pixel, helping you spot contamination, spoilage, and adulteration early. It enables real-time inspection during production, saving time and reducing costs compared to traditional lab tests. If you keep exploring, you’ll discover how this cutting-edge method is transforming the way we guarantee food quality and safety.

Key Takeaways

- Hyperspectral imaging offers rapid, non-destructive analysis of food products, detecting contamination and spoilage instantly.

- It captures detailed spectral fingerprints, enabling precise identification of adulteration and quality issues.

- The technology allows real-time, in-line inspection during manufacturing, reducing delays and costs.

- Advanced algorithms automatically flag suspicious samples, ensuring compliance with safety standards.

- Hyperspectral imaging enhances food safety, authenticity, and quality control, supporting industry and regulatory efforts.

Have you ever wondered how scientists detect subtle differences in materials or identify objects from afar? It’s a fascinating process made possible by spectral analysis, a technique that captures and interprets the light reflected or emitted by objects across many wavelengths. In the context of food safety, spectral analysis allows us to examine a product’s unique spectral fingerprint, revealing details invisible to the naked eye. This technology has become a game-changer in detecting food adulteration, where unscrupulous producers might add cheaper, harmful substances to increase weight or appearance. With hyperspectral imaging, you can analyze entire food items rapidly, pinpointing inconsistencies or contaminants that traditional methods might miss.

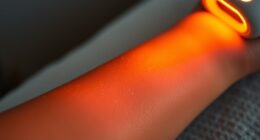

Hyperspectral imaging combines the power of spectroscopy and digital imaging to create detailed, high-resolution pictures that capture hundreds of spectral bands for each pixel. Unlike conventional cameras that record only visible light, hyperspectral cameras detect data across a broad spectrum, including infrared and ultraviolet. This means you gain a *thorough* view of the chemical composition, moisture content, and even the freshness of food products. When inspecting fruits, vegetables, or processed foods, hyperspectral imaging can identify areas of spoilage or contamination by analyzing their spectral signatures. It’s like giving food a detailed health check-up, but in seconds.

One of the most significant advantages of this technology is its ability to prevent food adulteration. For example, if someone tries to pass off diluted juice or contaminated spices, hyperspectral imaging can reveal differences in their spectral profiles compared to authentic samples. This detection process is fast, non-destructive, and highly accurate, reducing reliance on labor-intensive laboratory tests. As a result, food producers and regulators can ensure products meet safety standards before they reach consumers, minimizing health risks and economic losses.

You don’t need to be a scientist to appreciate how hyperspectral imaging streamlines food safety checks. It allows for real-time, in-line inspection during manufacturing, reducing delays and costs associated with traditional testing. With advanced algorithms, the technology automatically flags suspicious samples, enabling quick decision-making. *Furthermore*, because it’s non-invasive, you preserve the integrity of the food while examining it thoroughly. As hyperspectral imaging continues to evolve, expect even faster, more precise, and accessible solutions to combat food fraud and ensure that what reaches your plate is safe, genuine, and of high quality.

Frequently Asked Questions

How Cost-Effective Is Hyperspectral Imaging for Small-Scale Food Producers?

You might wonder about the cost-effectiveness of hyperspectral imaging for small-scale food producers. While the equipment has historically been expensive, advances are making it more affordable, leading to potential cost reductions over time. You can benefit from improved food safety checks without a significant financial burden, especially as prices decrease and scalability options grow. Ultimately, investing in hyperspectral technology could enhance your quality control while keeping equipment affordability in check.

What Are the Limitations of Hyperspectral Imaging in Detecting All Contaminants?

You should be aware that detection limitations of hyperspectral imaging can hinder its ability to identify all contaminants. Its effectiveness varies with contaminant diversity, meaning some harmful substances might go unnoticed if they don’t have distinct spectral signatures. While powerful, hyperspectral imaging isn’t perfect for every scenario. You might need supplementary methods to guarantee exhaustive food safety, especially when dealing with complex or unknown contaminant profiles.

How Long Does It Take to Implement Hyperspectral Imaging Systems in Food Facilities?

You’ll typically see the installation timeline for hyperspectral imaging systems range from a few weeks to several months, depending on your facility’s size and complexity. During this period, staff training is vital to guarantee proper operation and maintenance. Planning ahead for integration and training helps streamline the process, so you can start benefiting from faster, more accurate food safety checks within a reasonable timeframe, often around 3 to 6 months.

Can Hyperspectral Imaging Identify Specific Pathogens or Spoilage Organisms?

You can use hyperspectral imaging for pathogen detection and spoilage identification, but it doesn’t always pinpoint specific organisms. Instead, it detects changes in the food’s spectral signature that indicate contamination or spoilage. While it’s highly effective at spotting issues early, you might need additional tests for exact pathogen identification. Overall, hyperspectral imaging enhances safety checks by providing rapid, non-destructive spoilage detection.

What Training Is Required for Staff to Operate Hyperspectral Imaging Equipment?

You need to undergo operator training to effectively run hyperspectral imaging equipment, focusing on understanding how the system captures and analyzes data. Certification requirements vary, but typically, you’ll need to complete specific courses or hands-on training sessions. This guarantees you can operate the technology safely and accurately interpret results. Gaining proper training helps you meet industry standards and enhances your ability to maintain food safety using hyperspectral imaging.

Conclusion

As you embrace hyperspectral imaging, you’re opening a gentle new chapter in food safety. This innovative technology subtly enhances your ability to protect loved ones, ensuring only the best reach their tables. While it quietly transforms inspection processes, it also fosters peace of mind and trust. By choosing this path, you’re helping to nurture a safer, healthier future—one that’s worth cherishing and preserving with care and vigilance.