Laser cleaning uses focused light to remove rust and contaminants from surfaces safely without damaging the underlying material. You can target only the rust, ensuring a thorough clean while preserving the original surface. This method is fast, environmentally friendly, and suitable for delicate or intricate parts, making it ideal for various industries like aerospace and automotive. Want to discover how laser light can precisely restore metal surfaces? Keep exploring to find out more.

Key Takeaways

- Laser cleaning uses focused laser beams to precisely remove rust without damaging the underlying metal.

- The process effectively targets rust particles while preserving the original surface integrity.

- It is an environmentally friendly method, producing no secondary waste or hazardous residues.

- Laser rust removal is fast, reducing downtime compared to traditional abrasive or chemical methods.

- Suitable for delicate or intricate surfaces, laser cleaning offers safe, non-contact rust removal.

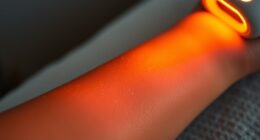

Laser cleaning is an innovative method that uses focused laser beams to remove dirt, rust, paint, and other contaminants from surfaces without damaging the underlying material. This technology is gaining popularity across various industries because of its efficiency and versatility. When you consider its industrial applications, you’ll find that laser cleaning is used extensively in manufacturing, aerospace, automotive, and power generation sectors. It effectively prepares surfaces for painting or coating without the need for harsh chemicals or abrasive tools. For example, in aerospace maintenance, laser cleaning can safely strip paint or corrosion from delicate components, ensuring safety and performance without risking damage. Similarly, in the automotive industry, it helps in removing rust and contaminants from parts before assembly or repair, streamlining production processes.

One of the key advantages of laser cleaning is its environmental benefits. Unlike traditional cleaning methods that often rely on chemical solvents, abrasives, or water-based solutions, laser cleaning produces no secondary waste. You won’t need to worry about hazardous residues or disposal issues, making it a cleaner option for the environment. It reduces the need for chemical cleaners, which can be harmful to ecosystems and human health, and minimizes water consumption and waste generation. Additionally, because laser cleaning is precise, it minimizes material waste and reduces the likelihood of damaging the surface underneath. This precision not only extends the lifespan of the parts being cleaned but also cuts down on the need for replacements, contributing further to sustainability.

The process itself is fast and efficient, often requiring less downtime compared to conventional methods. You can operate laser cleaning equipment with minimal preparation, and it’s adaptable to various surface sizes and shapes. The focused laser beam targets only the unwanted material, leaving the original surface intact. This means you get thorough cleaning without the risk of over-application or damage, making it suitable for delicate or intricate surfaces. Plus, laser cleaning is a dry process, so it doesn’t produce excess water or chemical runoff that could pollute nearby environments. Moreover, precise surface removal ensures that only contaminants are targeted, preserving the integrity of the underlying material.

Frequently Asked Questions

Is Laser Cleaning Environmentally Friendly Compared to Traditional Methods?

Yes, laser cleaning is more environmentally friendly than traditional methods. It reduces the environmental impact by eliminating the need for harsh chemicals and abrasive materials, which can pollute soil and water. You’ll appreciate the eco-friendly benefits, such as less waste and lower energy consumption. Plus, laser cleaning produces no secondary waste, making it a safer, cleaner option that supports sustainable practices in rust removal.

What Types of Rust Are Most Effectively Removed by Laser Cleaning?

Rust types like loose, flaky, and superficial rust respond particularly well to laser cleaning, as the laser’s light effectively targets surface corrosion. The effectiveness of removal diminishes with stubborn, deep-seated rust, but precision laser technology can often penetrate and treat various rust layers efficiently. You’ll find laser cleaning most effective on surface-level rust, making it ideal for delicate or valuable items needing careful, clean, and controlled rust removal.

How Does Laser Cleaning Affect the Underlying Material?

Laser cleaning gently removes rust without damaging the underlying material, helping you maintain material integrity and surface preservation. The laser targets only the rust particles, leaving the substrate untouched. This precise process prevents warping or pitting, ensuring your material remains strong and intact. You can confidently use laser cleaning on delicate surfaces, knowing it preserves the original surface quality while effectively eliminating rust.

What Safety Precautions Are Needed During Laser Rust Removal?

During laser rust removal, you need to prioritize safety by wearing protective eyewear to shield your eyes from laser radiation and guaranteeing skin shielding to prevent burns. Keep the area well-ventilated to avoid inhaling fumes. Use proper signage and barriers to restrict access. Always follow manufacturer guidelines and receive proper training to handle equipment safely. Taking these precautions helps prevent injuries and ensures effective, safe rust removal.

Can Laser Cleaning Be Used on Delicate or Historical Artifacts?

Laser cleaning is like a gentle touch on delicate artifacts, making it ideal for preservation. You can safely use it on historical pieces, provided experts tailor the process for artifact safety. The precision of laser technology ensures that only rust and contaminants are removed without harming the underlying material. With proper technique, laser cleaning maintains the integrity of delicate artifacts while achieving effective rust removal.

Conclusion

Laser cleaning is like wielding a gentle but powerful brush of light, effortlessly banishing rust without damage. By choosing this innovative method, you’re not just cleaning—you’re giving your surfaces a fresh start, shining brighter than ever. Embrace the future of restoration with laser technology, turning the battle against rust into a dance with light. Trust in this radiant solution to keep your surfaces pristine, as smooth and bright as a shining star.