If you’re comparing laser cutting and waterjet cutting regarding energy and light, you’ll find that laser cutting uses focused light beams to melt or vaporize material with high precision, making it energy-efficient for thin sheets. In contrast, waterjets rely on high-pressure water streams, which consume more energy and don’t involve heat, preserving material quality. To understand how each method impacts your project’s efficiency and material choice, explore the details further.

Key Takeaways

- Laser cutting uses focused light energy to melt or vaporize material, while waterjet relies on high-pressure water force.

- Laser cutting involves heat, potentially affecting material integrity; waterjets operate cold, avoiding thermal distortion.

- Laser systems are more energy-efficient for thin, precise cuts; waterjets consume more energy due to high-pressure and abrasive use.

- Laser beams deliver concentrated light energy for detailed, fine cuts; waterjets use physical force suitable for thicker, heat-sensitive materials.

- Choice depends on material thickness, desired precision, and energy considerations, balancing light energy versus mechanical force.

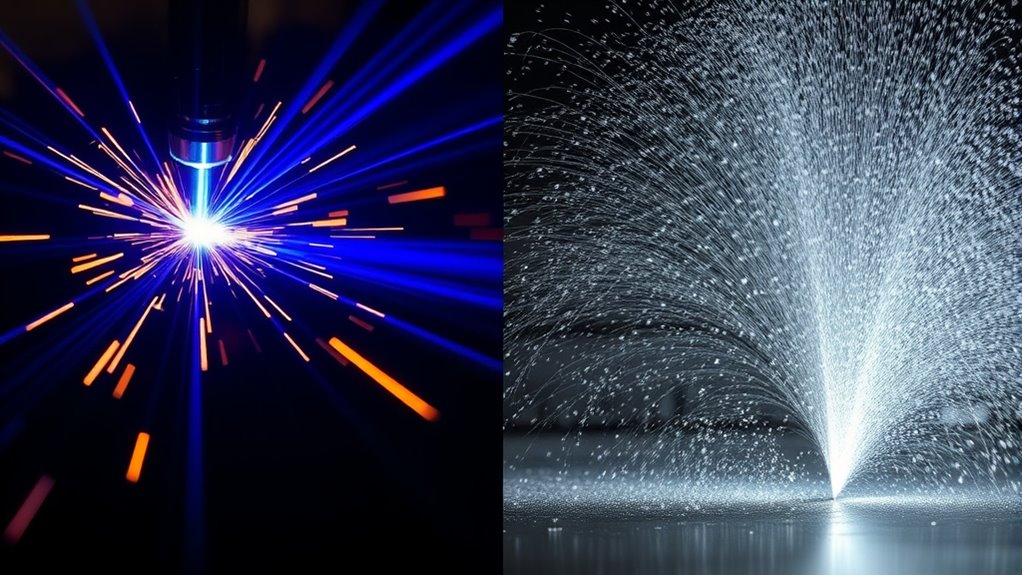

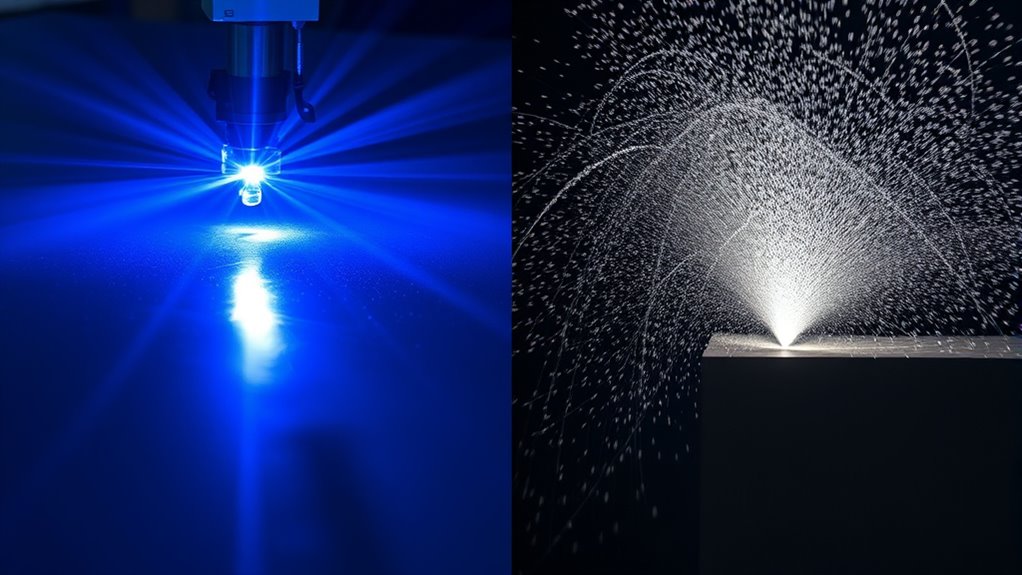

When deciding between laser cutting and waterjet cutting, understanding their differences is vital for choosing the right technology for your project. Both methods harness energy and light differently, impacting how effectively they cut various materials. Laser cutting relies on a focused beam of light to melt, burn, or vaporize material, making it highly precise, especially for intricate designs. Waterjet cutting, on the other hand, uses a high-pressure stream of water, often mixed with abrasive particles, to carve through material. While waterjets excel at cutting thicker, more resistant materials without heat-affected zones, lasers are better suited for thin, delicate, or precise applications.

Choosing between laser and waterjet cutting depends on material thickness, precision needs, and heat sensitivity.

In the domain of fiber optics, laser technology shines brightly because it uses light energy to achieve exceptional cutting precision. Fiber lasers, a specific type of laser, deliver concentrated, coherent light that can be finely tuned, allowing for ultra-precise cuts with minimal kerf width. This precision is vital when working with delicate components like fiber optics themselves or thin sheets of metal and plastic. The laser’s ability to focus light into a narrow beam provides a level of detail unmatched by waterjet cutting, making it ideal for applications where exact dimensions and fine features are critical.

Waterjet cutting, however, doesn’t rely on light but on the physical force of water under extremely high pressure. It’s a cold cutting process, meaning it doesn’t introduce heat that could distort or damage sensitive materials. This makes waterjets preferable for cutting thick, heat-sensitive materials, such as certain composites or stone. While waterjets may lack the microscopic precision of lasers, they’re still capable of producing smooth, clean edges and can cut through virtually any material, including metals, glass, and ceramics, with high accuracy.

Energy consumption also varies markedly between the two. Laser cutting tends to be more energy-efficient for thin materials, as it concentrates energy precisely where needed. Waterjet systems generally consume more energy because they generate and maintain high-pressure streams and often require extensive abrasive usage. However, waterjet cutting’s ability to handle thicker and more diverse materials without heat makes it indispensable for specific industrial applications.

Frequently Asked Questions

How Does Energy Consumption Compare Between Laser and Waterjet Cutting?

You’ll find that laser cutting is generally more energy-efficient than waterjet cutting, consuming less power for similar tasks. Laser cutters use focused light energy, which results in lower overall power consumption and quicker operation times. Waterjet cutting tends to use more energy due to high-pressure pumps and extensive water use. So, if energy efficiency matters, laser cutting often offers a more cost-effective solution with lower power consumption.

What Are the Environmental Impacts of Each Cutting Method?

You’ll want to weigh the environmental footprints of laser and waterjet cutting. Laser cutting often produces fumes and hazardous waste, complicating waste management and increasing environmental impact. Waterjet cutting, however, uses water and abrasives, which can be recycled but may cause water waste. Both methods impact ecosystems differently, so you should consider sustainable practices, such as recycling waste materials and minimizing emissions, to lessen their ecological effects.

Can Both Methods Cut All Types of Materials Equally Well?

You’ll find that neither method can cut all materials equally well due to material limitations and cutting versatility. Laser cutting works best with metals, plastics, and some fabrics, but struggles with thick or reflective materials. Waterjet cutting, on the other hand, handles a wider range of materials, including stone, glass, and composites, offering greater cutting versatility. Both have their strengths, but their effectiveness depends on the specific material you need to cut.

How Does the Light Source Affect Cutting Precision?

Just like a master archer needs pinpoint accuracy, your choice of light source in laser cutting directly influences precision. A focused beam enhances beam focus accuracy, ensuring cleaner cuts and tighter tolerances. If the light source isn’t stable or well-focused, it’s like aiming with a blurry sight—your precision drops. So, selecting a high-quality, stable light source is essential for achieving the best cut quality and detailed results.

What Safety Measures Are Necessary for Each Cutting Technique?

You need to wear proper personal protective equipment, like safety glasses and gloves, to safeguard yourself from hazards during laser or waterjet cutting. Regular equipment maintenance is essential to guarantee safe operation and prevent malfunctions. Keep the work area well-ventilated, and follow manufacturer safety guidelines. Always stay alert and trained on emergency procedures, and never bypass safety features to reduce risks associated with each cutting technique.

Conclusion

When choosing between laser and waterjet cutting, consider not just the immediate results but the subtle echoes of each method’s energy and light. Sometimes, one approach gently guides you toward efficiency, while the other softly reminds you of the importance of precision and versatility. Ultimately, your decision shapes the quiet harmony between innovation and sustainability, allowing your projects to flourish in a way that subtly honors both your goals and the environment’s delicate balance.