Laser and LED technologies have transformed manufacturing by harnessing the unique properties of coherent and incoherent light. Lasers offer high precision, focused beams, and consistent wavelengths, enabling cutting, welding, and detailed material processing. LEDs provide energy-efficient illumination and reliable surface inspections. These advancements have increased accuracy, speed, and safety in production lines. If you explore further, you’ll uncover how these innovations keep shaping industries and opening new possibilities every day.

Key Takeaways

- Coherent laser light enables precise, focused processing like cutting and welding, transforming manufacturing accuracy and efficiency.

- Lasers’ monochromatic, stable wavelengths ensure uniform results, reducing waste and improving product quality.

- LED technology offers energy-efficient, stable illumination for inspection and quality control, enhancing surface analysis.

- Advances in laser coherence and miniaturization have led to faster, more versatile manufacturing tools and medical devices.

- The combination of laser and LED innovations has revolutionized industry capabilities, enabling high-precision, cost-effective production processes.

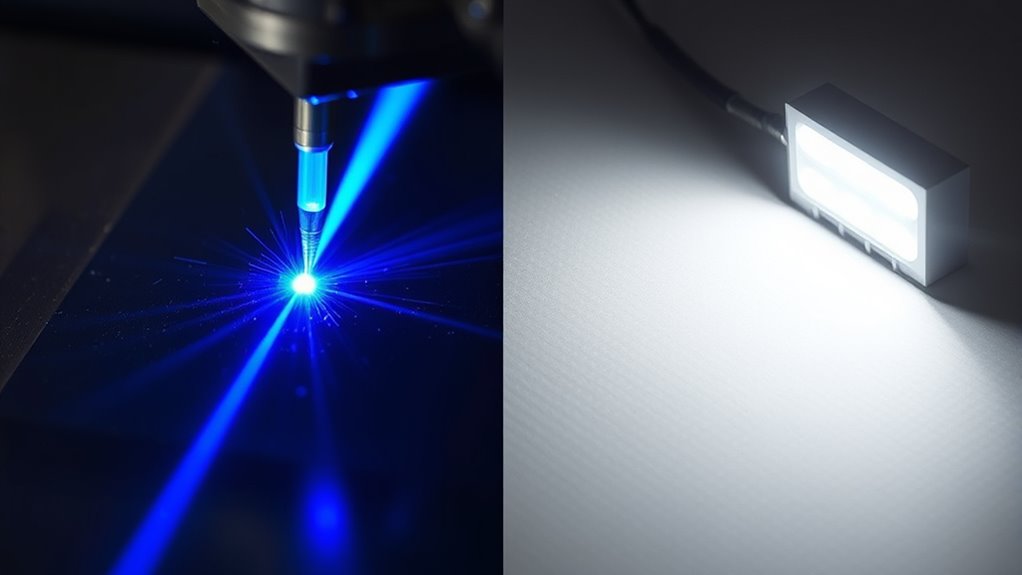

The Fundamental Differences Between Laser and LED Light Sources

While both laser and LED light sources emit visible light, their fundamental differences lie in how they produce and control that light. Lasers generate highly coherent and monochromatic light, resulting in narrow spectral characteristics that can be finely tuned. This coherence allows for precise focusing and minimal divergence. LEDs, on the other hand, emit incoherent light with broader spectral characteristics, covering a wider range of wavelengths. When it comes to power stability, LEDs tend to offer more consistent output over time, making them reliable for many applications. Lasers require careful stabilization systems to maintain consistent power levels, especially in demanding manufacturing processes. Additionally, understanding light coherence is essential for selecting the appropriate source for specific manufacturing tasks. Overall, these differences influence their suitability for specific tasks, with lasers excelling in precision and LEDs providing durability and stability.

How Coherence Enhances Precision in Manufacturing Processes

Coherence in laser light considerably boosts precision in manufacturing by enabling tight focus and minimal divergence. With high beam coherence, your laser can maintain a consistent phase relationship across its wavefront, allowing you to concentrate energy precisely where needed. This results in cleaner cuts, more accurate welds, and finer detail. Wavelength stability also plays a vital role, ensuring that the laser consistently emits at a specific wavelength, reducing variability in processing results. Stable wavelengths lead to better control over material interactions, improving quality and repeatability. Additionally, beam quality directly influences the effectiveness of laser applications, as higher beam quality corresponds to more precise and efficient processing. By leveraging beam coherence and wavelength stability, you gain the ability to perform delicate tasks with higher accuracy and efficiency. This precision is essential for advanced manufacturing, where tight tolerances and consistency matter most.

The Impact of Laser Technology on Cutting, Welding, and Material Processing

Laser technology has revolutionized cutting, welding, and material processing by providing unmatched accuracy and control. Its precision allows you to cut complex shapes and weld delicate materials with minimal heat affected zones. Fiber optics play a vital role by transmitting laser beams efficiently, enabling long-distance precision operations and integration into automated systems. You’ll find lasers essential in manufacturing industries, where they improve speed and quality. Furthermore, laser technology has advanced medical instrumentation, where its precision benefits surgical procedures and tissue welding. This technology’s ability to focus intense energy precisely makes it ideal for high-speed cutting, welding, and surface treatments. Additionally, remote hackathons facilitate collaboration among global teams, often employing laser-like focus in virtual problem-solving environments. This technology’s ability to focus intense energy precisely makes it ideal for high-speed cutting, welding, and surface treatments. As a result, you experience improved productivity, reduced waste, and higher-quality output, transforming traditional manufacturing processes into highly efficient, precise operations.

LED Applications in Display, Lighting, and Quality Inspection

LEDs play a vital role in modern display technologies, providing bright, energy-efficient visuals for screens and signage. They also enable precise lighting solutions that enhance image quality and visibility. Additionally, LEDs are essential in quality inspection systems, offering accurate, real-time analysis of products and surfaces. In the automotive sector, Kia Tuning often incorporates LED lighting for both aesthetic and functional improvements, demonstrating the versatility of LED applications.

Visual Display Technologies

Have you ever wondered how advanced display and lighting solutions enhance our daily lives? Quantum optics plays a vital role here, especially through spectral coherence, which allows LEDs to produce precise, vibrant colors. This coherence improves image sharpness and color accuracy in modern displays, making visuals more lifelike. In lighting, spectral coherence helps create consistent illumination with minimal energy loss, enhancing overall quality. LED technology benefits from the principles of quantum optics, enabling controlled emission spectra and higher efficiency. These features lead to brighter screens, richer colors, and better contrast. Whether in TVs, smartphones, or industrial displays, the integration of coherent light sources ensures visuals are clearer and more vivid, transforming how we experience digital content daily. Additionally, advancements in automation technologies contribute to manufacturing processes by increasing precision and reducing errors in production.

Precision in Inspection

Building on the advancements in spectral coherence that enhance display quality, LEDs now play a crucial role in precision inspection across various industries. Their spectral stability guarantees consistent, reliable results, enabling you to detect even the tiniest defects or inconsistencies. LEDs’ power efficiency allows for prolonged inspection processes without excessive energy consumption, reducing costs and environmental impact. Their ability to produce specific wavelengths with minimal fluctuation improves measurement accuracy, making them ideal for quality control in manufacturing. Additionally, proper storage of LED sources ensures sustained spectral stability and performance over time. Whether inspecting electronic components, evaluating surface finishes, or verifying assembly accuracy, LEDs deliver high-resolution illumination that reveals defects invisible to the naked eye. This combination of spectral stability and power efficiency makes LEDs an essential tool for modern precision inspection, ensuring products meet strict quality standards efficiently.

Safety Considerations and Challenges of Using Coherent Light

Using coherent light such as lasers presents unique safety challenges that demand careful attention. The primary concern is eye safety, as direct or reflected laser beams can cause serious eye damage or blindness. Radiation hazards are also significant, especially with high-powered lasers that emit harmful ultraviolet or infrared radiation. To stay safe, you should be aware of these risks and follow proper protocols. Additionally, understanding the reservoir system in self-watering planters can help prevent overexposure to moisture-related hazards. Here are four key safety considerations:

- Always wear appropriate protective eyewear rated for the laser’s wavelength.

- Use beam enclosures and barriers to prevent accidental exposure.

- Implement safety training for all operators handling lasers.

- Regularly inspect equipment for potential radiation leaks or damage.

Being vigilant helps mitigate risks and ensures safe operation in environments using coherent light.

Future Trends and Innovations Driven by Laser and LED Technologies

Advancements in laser and LED technologies are shaping the future of various industries, from healthcare to consumer electronics. Quantum optics is *releasing* new possibilities in precision, enabling ultra-compact devices that harness coherent light for faster data transmission and improved imaging. Photonic integration is streamlining complex systems, making them more efficient and cost-effective. Expect innovations like miniaturized laser modules for medical diagnostics or advanced LED displays with enhanced color accuracy. As these technologies evolve, you’ll see smarter, more energy-efficient devices that leverage quantum optics principles for superior performance. The convergence of laser and LED advancements will drive significant breakthroughs, transforming manufacturing processes, communication systems, and consumer products, ultimately making cutting-edge technology more accessible and versatile across multiple sectors. Enhanced laser tuning techniques are also paving the way for even greater precision and customization in various applications.

Frequently Asked Questions

How Do Laser and LED Light Sources Differ in Energy Efficiency?

You’ll notice that laser and LED light sources differ markedly in energy efficiency. Lasers offer higher power density and spectral purity, which means they deliver focused, intense light with less energy loss. LEDs, on the other hand, are more energy-efficient for general illumination but lack the same spectral purity and power density. So, for precision tasks requiring high energy efficiency, lasers are often the better choice, while LEDs suit broader, less demanding applications.

What Environmental Impacts Are Associated With Laser and LED Manufacturing?

Imagine your choices as a ripple in a pond; they impact the environment. Laser and LED manufacturing can create recycling challenges and generate material waste, harming ecosystems. LEDs tend to be more eco-friendly, but both require rare materials, leading to resource depletion. By understanding these impacts, you can advocate for sustainable practices, ensuring your tech use supports environmental health rather than adding to the problem.

Can Laser and LED Technologies Be Combined for Advanced Manufacturing Solutions?

You can definitely combine laser and LED technologies for advanced manufacturing through hybrid integration. Multi modal systems allow you to leverage the strengths of both, such as precision from lasers and energy efficiency from LEDs. This integration enhances flexibility, enabling you to perform diverse tasks more effectively. By adopting these multi modal systems, you’ll improve process efficiency, reduce costs, and open new possibilities for innovative manufacturing solutions.

How Do Costs Compare Between Laser and LED Equipment Over Their Lifespan?

Imagine weighing a sleek, high-tech laser against a simple LED. Your cost analysis shows that lasers often have higher upfront prices but longer lifespans, reducing replacement costs. LEDs are cheaper initially but may need more frequent replacements, increasing long-term expenses. Over their lifespan, LEDs generally cost less, but lasers offer precision benefits. So, your choice depends on balancing initial investments with long-term operational costs.

What Are the Maintenance Requirements for Laser Versus LED Systems?

You should know that laser systems often require more maintenance, such as frequent calibration, due to their complex optics, and their diode lifespan can be shorter if not properly maintained. LED systems generally need less upkeep, with longer diode lifespans and minimal calibration. Regular cleaning and monitoring help guarantee both systems stay ideal, but lasers demand more attention to calibration frequency to maintain precision and performance over time.

Conclusion

You’ve seen how lasers and LEDs revolutionize manufacturing, each with unique strengths. Did you know that laser cutting accounts for over 40% of industrial material processing? As technology advances, expect even greater precision and efficiency. Embracing these coherent light sources will keep you ahead, optimizing quality and safety. Staying informed about innovations guarantees you leverage their full potential, transforming your production processes for the future.