Photonic crystals are revolutionizing industries by giving you advanced ways to manipulate light at the microscopic level. They improve data transmission in telecom, enhance medical imaging, and make energy-efficient displays possible. Although manufacturing these crystals at large scales remains challenging, ongoing innovations are reducing costs and improving quality. As this technology continues to evolve, it’s opening new opportunities across many sectors. Keep exploring to uncover how photonic crystals can impact your industry and future applications.

Key Takeaways

- Photonic crystals enable advanced light manipulation for telecommunications, sensing, imaging, and display technologies.

- Manufacturing challenges include producing defect-free, large-scale, and uniform photonic crystals cost-effectively.

- Progress in nanofabrication and materials science is improving mass production capabilities.

- Applications include high-efficiency optical fibers, medical diagnostics, energy-efficient displays, and environmental sensors.

- Decreasing costs and ongoing R&D are driving industry adoption and innovative uses of photonic crystal technologies.

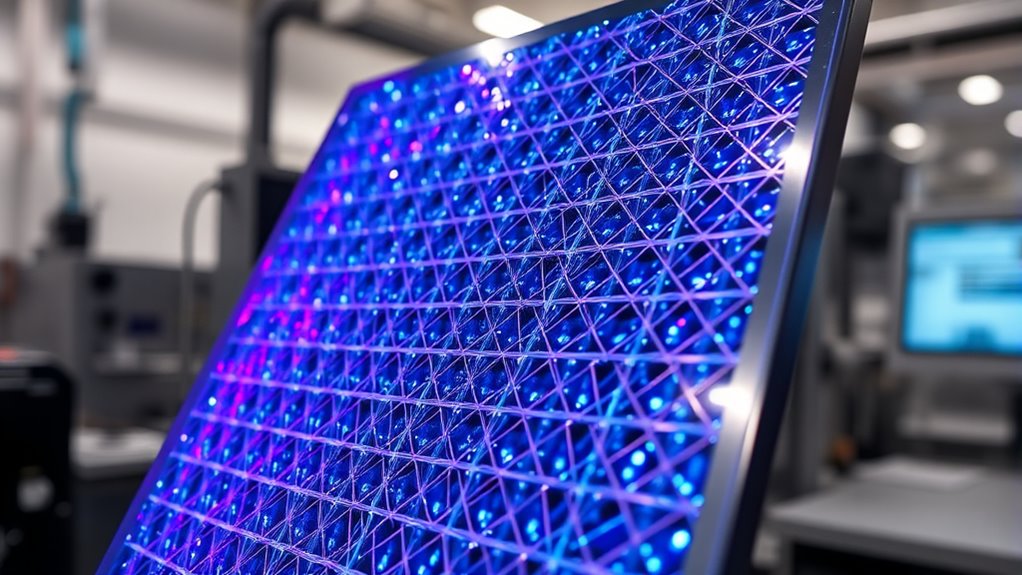

Have you ever wondered how photonic crystals are revolutionizing industrial applications? These remarkable structures manipulate light in ways that were once thought impossible, opening up new avenues across various sectors. As exciting as their potential is, integrating photonic crystals into manufacturing processes isn’t without its hurdles. Manufacturing challenges, such as producing defect-free crystals at scale and ensuring consistent quality, can be be significant. The intricate nanostructures require precise fabrication techniques, often involving expensive equipment and complex procedures. Achieving uniformity across large batches remains a hurdle, which affects the scalability for commercial use. Despite these obstacles, advancements in nanofabrication and material science are steadily improving production methods, making mass manufacturing more feasible. Overcoming these challenges is essential for accessing the full market potential of photonic crystals, which is rapidly expanding across numerous industries. Additionally, understanding the importance of materials and enzymes can enhance the development of more efficient fabrication techniques.

Market applications are broadening as industries recognize the unique capabilities of photonic crystals. In telecommunications, they enhance data transmission by improving the efficiency of optical fibers and lasers, enabling faster and more reliable networks. In the medical field, photonic crystals are used for high-precision sensing and imaging, allowing for minimally invasive diagnostics and targeted treatments. The display and lighting industries benefit from photonic crystals by creating more vibrant, energy-efficient screens and lighting systems. Environmental sensors also utilize these structures to detect pollutants with high sensitivity, facilitating more effective monitoring of air and water quality. Additionally, the automotive and aerospace sectors are exploring photonic crystals for advanced optical components, improving safety and performance. The versatility of these crystals stems from their ability to control light at the nanoscale, which translates into better performance and new functionalities in existing products.

While the market applications are promising, widespread adoption hinges on resolving manufacturing challenges. As production techniques become more refined, costs will decrease, making photonic crystal-based solutions more accessible. This will open doors to even more innovative applications, from smart windows that regulate heat and light to highly efficient solar cells. The pace of research and development is accelerating, driven by industry needs for better performance and sustainability. As a result, the future of photonic crystals in industry looks bright, with the potential to transform how we manipulate light in everyday technology. If you’re involved in manufacturing or industrial innovation, keeping an eye on these developments could position you at the forefront of a new technological wave, where photonic crystals become integral to product design and performance.

Frequently Asked Questions

How Cost-Effective Are Photonic Crystals for Large-Scale Manufacturing?

Photonic crystals can be cost-effective for large-scale manufacturing because they enable significant cost reduction by improving device efficiency and performance. As you scale up production, manufacturing scalability becomes more feasible, lowering per-unit costs. Although initial setup might be expensive, the long-term benefits include reduced material waste and energy savings. Overall, with advancements in fabrication techniques, photonic crystals are increasingly viable for cost-efficient mass production, making them a smart choice for industry deployment.

What Are the Environmental Impacts of Producing Photonic Crystals?

You should be aware that producing photonic crystals can lead to environmental pollution if manufacturing processes release harmful chemicals or waste. Additionally, resource depletion may occur due to the extraction of raw materials like rare minerals. To minimize these impacts, it’s vital to adopt sustainable practices, recycle materials, and implement cleaner production techniques. This approach helps protect ecosystems while advancing photonic crystal technology.

Can Photonic Crystals Be Integrated With Existing Optical Technologies?

You can definitely integrate photonic crystals with existing optical technologies, but you should consider their integration potential carefully. Compatibility challenges may arise due to differences in fabrication methods or material properties, which might require adjustments or new techniques. However, with ongoing research and development, overcoming these hurdles is feasible, making photonic crystals a promising addition to enhance the performance of current optical systems.

What Are the Limitations of Photonic Crystals in Industrial Applications?

You’ll face limitations with photonic crystals in industry mainly due to scalability challenges and fabrication precision. Producing large-scale, defect-free structures can be tough, which hampers mass manufacturing. Additionally, maintaining the exact periodicity needed for ideal performance is challenging, potentially reducing efficiency. These issues make it hard to fully integrate photonic crystals into existing optical systems, but ongoing research aims to overcome these hurdles for broader industrial use.

How Does the Durability of Photonic Crystals Compare to Traditional Materials?

You’ll find that photonic crystals generally have lower durability compared to traditional materials due to their complex nanostructures, which can be more prone to damage from environmental factors like moisture and physical stress. Their material resilience isn’t as high, making them less suitable for long-term, high-stress industrial applications. However, ongoing research aims to improve their durability, which could eventually enhance their resilience and expand their industrial uses.

Conclusion

You can see that photonic crystals are transforming industries with their unique light-manipulating abilities. As technology advances, they’ll open doors to innovations you might not have imagined. Don’t forget, when it comes to staying ahead, it’s often about thinking outside the box. Embracing these materials now means you’re setting yourself up for success in the future. Keep an eye on photonic crystals—they’re a game-changer you won’t want to miss.