Laser sintering uses focused light, typically a high-powered laser, to selectively fuse fine metal powders layer by layer. By carefully controlling laser parameters like power and speed, you can create complex, precise metal parts with excellent strength and density. This process allows for rapid, customized production of intricate geometries that traditional methods can’t easily achieve. If you look deeper into this topic, you’ll discover how optimizing powder properties and laser settings can facilitate even more manufacturing possibilities.

Key Takeaways

- Laser sintering utilizes a focused laser beam to selectively fuse metal powder particles layer by layer.

- Precise laser control enables complex, high-resolution metal 3D printing with tailored mechanical properties.

- Proper laser parameters are essential to ensure complete fusion, strong bonds, and high-density metal parts.

- Metal powders must have specific properties like flowability and melting points for optimal sintering results.

- This technology is ideal for producing durable, intricate metal components in industries like aerospace and medical devices.

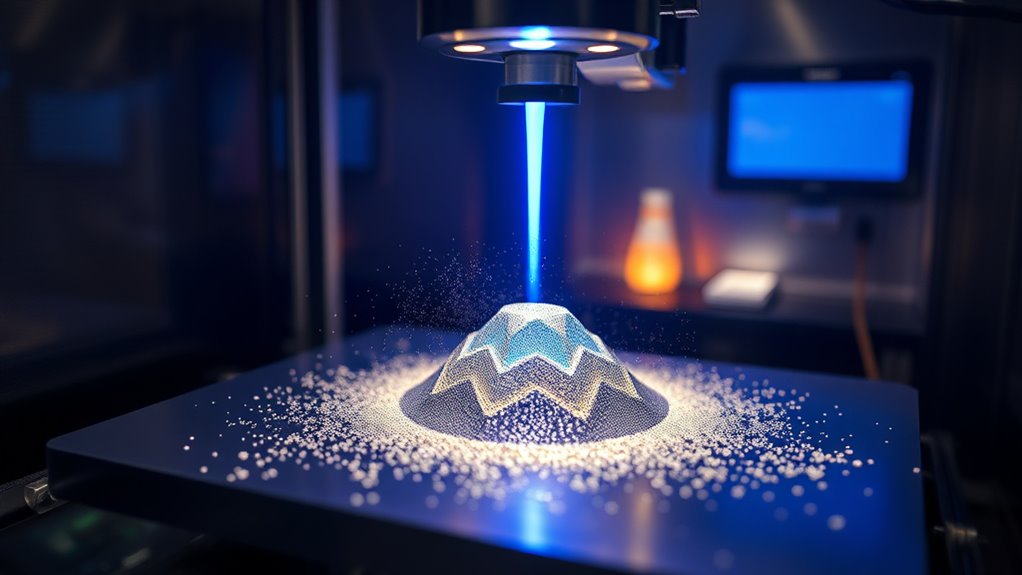

Have you ever wondered how complex, durable 3D objects are made quickly and efficiently? Laser sintering is revolutionizing the way metals are shaped into precise components, and understanding its core process can give you insight into this cutting-edge technology. At the heart of laser sintering, you’ll find metal powder—fine, uniformly sized particles that serve as the raw material. These powders are carefully selected based on their melting points, flowability, and compatibility with the laser process. When you use laser sintering, you direct a high-powered laser beam onto the metal powder bed, selectively fusing the particles together layer by layer to build the desired object. The success of this process hinges greatly on the laser parameters, which include laser power, scanning speed, and spot size. Adjusting these parameters allows you to control the energy delivered to the powder, influencing the density, mechanical properties, and surface finish of the final product.

Getting the laser parameters right is vital because it determines how well the metal powder melts and bonds. Too much laser power, and you risk overheating the material, causing warping or degradation of properties. Too little, and the particles won’t fuse properly, resulting in weak spots or incomplete structures. The scanning speed also matters; moving the laser too quickly might leave gaps between melted areas, while moving too slowly can lead to excess heat buildup, affecting dimensional accuracy. Spot size influences the precision of the sintering process—smaller spots provide finer detail but may increase processing time, while larger spots speed up production but might sacrifice some resolution. Furthermore, understanding the metal powder properties is essential for optimizing the process and ensuring consistent results.

Proper laser settings are crucial for optimal metal fusion and part quality.

The process is highly controlled and repeatable, making laser sintering ideal for creating complex geometries that would be challenging with traditional manufacturing. You can produce intricate lattice structures, internal channels, or custom-engineered parts with high precision. As you fine-tune the laser parameters, you optimize the quality and mechanical strength of your metal parts, ensuring they meet specific performance standards. This ability to manipulate the process parameters gives you a powerful tool for innovation in industries like aerospace, automotive, and medical devices, where material performance and precision are critical.

In essence, laser sintering harnesses focused light to transform metal powder into solid, functional objects, offering a fast, flexible, and highly precise method for metal 3D printing. By understanding and controlling the interplay between metal powder properties and laser parameters, you can achieve outstanding results in rapid manufacturing, pushing the boundaries of what’s possible with additive metal fabrication.

Frequently Asked Questions

What Types of Metals Can Be Used in Laser Sintering?

You can use a variety of metal alloy options in laser sintering, including stainless steel, titanium, aluminum, and cobalt-chrome. These metals are popular because of their excellent corrosion resistance and mechanical properties. When choosing metals for laser sintering, consider their melting points and compatibility with the process. This flexibility lets you create complex, durable parts suited for aerospace, medical, and industrial applications.

How Does Laser Sintering Compare to Traditional Metal Manufacturing?

Imagine you’re comparing laser sintering to traditional methods like casting. Laser sintering offers higher cost efficiency and faster production speeds, especially for complex geometries. It reduces material waste and shortens lead times, making it ideal for rapid prototyping and small batch production. While traditional methods excel in large-scale, high-volume manufacturing, laser sintering gives you flexibility and speed, enabling quicker innovation and customization.

What Are the Safety Considerations for Laser Sintering Equipment?

When working with laser sintering equipment, you should prioritize safety by following laser safety protocols, including wearing proper eye protection and ensuring controlled access to the area. Regular equipment maintenance is essential to prevent malfunctions and guarantee peak performance. Always inspect the laser system for damage, keep the workspace clean, and follow manufacturer guidelines. This proactive approach reduces risks and maintains a safe environment during the metal 3D printing process.

Can Laser Sintering Produce Complex Internal Geometries?

Did you know that nearly 70% of engineers say complex internal geometries boost part performance? With laser sintering, you can create intricate internal channels and lattice structures that traditional manufacturing can’t match. This process allows for precise control, enabling you to produce lightweight yet strong components. So, yes, laser sintering excels at producing complex internal geometries, opening new possibilities in aerospace, medical, and automotive industries.

What Are the Post-Processing Steps After Laser Sintering?

After laser sintering, you typically start with surface finishing to smooth out rough areas and improve the appearance. Next, you may perform heat treatment to relieve internal stresses and enhance mechanical properties. These post-processing steps guarantee your metal part reaches its desired quality, strength, and surface quality. Proper finishing and heat treatment are essential to optimize the performance and durability of your 3D-printed metal components.

Conclusion

You’ve seen how laser sintering uses focused light to create intricate metal parts with precision. This cutting-edge tech is like having a modern blacksmith’s forge, but way faster and more versatile. As you step into the future of manufacturing, remember that even the most advanced machines are just the modern equivalent of those ancient tools—only now, powered by beams of light instead of sparks. Embrace it, and watch your ideas come to life!